Buttweld Fitting

Buttweld Fitting Manufacturer

Buttweld Fitting Manufacturer:

In the field of welded fittings, buttweld fittings (ASME B16.9) are essential parts. The main benefit of these fittings is that they may be joined without the need to cut materials into precise shapes thanks to their seamless welding method. Simply matching the ends of two metals, then welding them together to create a strong bond, is how Butt Weld Fittings Manufacturers in India join them. Manufacturers of industrial pipe fittings use this effective welding technique to forge a solid and long-lasting bond between the two metals.

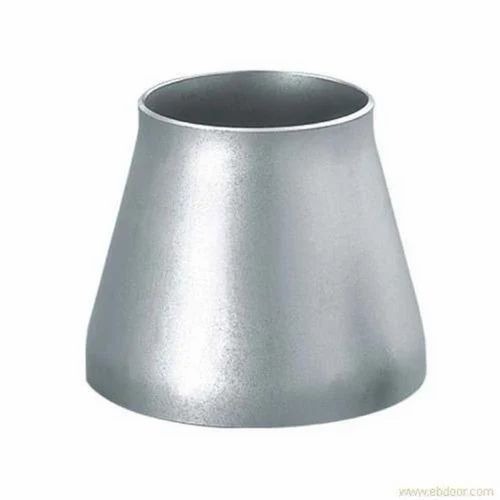

Bullion Pipe & Tubes is a high-quality Buttweld Fittings Manufacturer. Our expertise lies in manufacturing and supplying a wide range of pipe fittings including elbows, tees, cross, reducers, caps, and more. Specifically designed to ensure a secure and dependable connection between pipes made of different materials and sizes. They are widely applicable in avid industries. Buttweld Fittings of superior quality manufactured by Bullion Pipe & Tubes. We specialize in elbows, tees, cross, reducers, caps and various other types of pipe fittings. Buttweld fittings are designed to provide a leak-proof and reliable connection between pipes of different sizes and materials. They are commonly used in industries such as oil and gas, chemical processing, and water treatment. Buttweld fittings are made from a variety of materials, including carbon steel, stainless steel, and alloy steel. Each material has its own unique properties and is chosen based on the application and environmental factors.

Specifications of Buttweld Fittings:

Dimensions and Size Range:

Our buttweld fittings come in a wide range of sizes to accommodate various pipe dimensions, from small bore piping to large diameter pipes. Common sizes include:

- Elbows: ½” to 48” (DN15 to DN1200)

- Tees: ½” to 48” (DN15 to DN1200)

- Reducers: ½” to 48” (DN15 to DN1200)

- Caps: ½” to 48” (DN15 to DN1200)

- Crosses: ½” to 48” (DN15 to DN1200)

- Stub Ends: ½” to 48” (DN15 to DN1200)

Surface Finish:

To maintain the highest standards of hygiene and resistance to corrosion, especially in industries like pharmaceuticals and food processing, our fittings can be provided with the following finishes:

- Pickled and Passivated: To remove oxide layers and prevent further oxidation.

- Polished: For clean, smooth, and aesthetically appealing finishes.

- Sandblasted: For a matte surface suitable for industrial applications.

Applications of Buttweld Fittings:

Buttweld fittings are essential in many industries due to their ability to provide strong, leak-free connections that can withstand high-pressure, high-temperature, and corrosive environments. Some key applications include:

- Oil and Gas Industries:

Buttweld fittings are extensively used in the oil and gas Industries to join pipes carrying crude oil, natural gas, refined petroleum products, and chemicals. Their ability to withstand high pressures and corrosive environments makes them ideal for both upstream and downstream operations, such as drilling, refining, and transportation. - Chemical and Petrochemical Plants:

The chemical and petrochemical industries rely on buttweld fittings for safe, efficient, and secure transportation of chemicals, gases, and hazardous materials. These fittings ensure the integrity of the pipeline system and prevent leaks or failures that could result in costly downtime or safety risks. - Power Generation:

Buttweld fittings are integral to power generation plants, where they are used in steam, water, and gas systems. These fittings are essential for maintaining the efficient flow of fluids through systems, whether in thermal, nuclear, or renewable energy power plants. Their robust construction ensures reliable and long-lasting performance in demanding environments. - Water Treatment Plants:

In water treatment plants, buttweld fittings are used to connect pipes in critical stages of water filtration and distribution. These fittings are ideal for systems that require corrosion resistance, particularly in areas with high levels of chloride or other corrosive agents. - Pharmaceutical and Food Processing:

The pharmaceutical and food processing industries demand hygiene and safety. Buttweld fittings used in these industries are carefully designed to meet cleanliness and safety standards. They are commonly used in the transportation of liquids, such as water, chemicals, or ingredients, within the manufacturing process.

Why Choose Bamlia Industries?

- Precision Engineering: We utilize the latest technologies and manufacturing techniques to ensure each buttweld fitting is crafted with precision, achieving perfect welding and dimensional accuracy.

- Material Variety: Our fittings are available in a wide array of materials, ensuring compatibility with a variety of industrial environments, from highly corrosive to extreme-temperature conditions.

- Customization and Flexibility: We understand that every project has unique requirements. Our team works closely with clients to offer custom dimensions, designs, and materials, providing the perfect fit for any pipeline system.

- Strict Quality Control: Our buttweld fittings undergo rigorous testing, including hydrostatic, ultrasonic, and visual inspections, to ensure that each product meets Industries standards such as ASME, ANSI, ASTM, and ISO.

- Timely Deliveries: We prioritize timely production and delivery, ensuring that our clients receive their products as per schedule, even for large orders or special projects.

- Cost-Effective Solutions: Despite offering high-end quality and custom solutions, we maintain competitive pricing, helping businesses reduce overall project costs without compromising on quality.

Get in Touch with Us

If you’re in need of high-quality, reliable, and custom buttweld fittings, look no further than Bamlia Industries. We are committed to providing outstanding products and services that support your success, no matter the size or scope of your project.

Contact us today for a quote, detailed product information, or to discuss your unique requirements. Our dedicated team is ready to assist you in selecting the perfect fittings for your pipeline needs.